In business, the Product Development Cycle and the Employee Lifecycle are common terms and concepts in the business lexicon. What about the concept of the Process Lifecycle?

Such a concept is not commonly discussed among quality circles, traditional LEAN practitioners, nor Six Sigma advocates. The fact of the matter is most Lean Six Sigma Belt practitioners join a company and improve existing process. In fact, employees can experience their own employee lifecycle inside a company practicing continuous improvement on processes that have been in place for years (maybe even decades) without giving much thought to the Process Lifecycle itself.

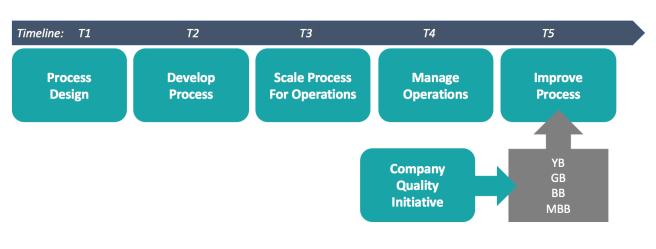

I have given some thought to this topic. The diagram below is my understanding of what I call the Process Lifecycle. Like a product or an employee, the process itself has a lifecycle.

The Process Lifecycle begins with process design. Process Design might be triggered by a new service/product offering or it might be triggered by improvements in the technology used to deliver existing service/product. Either way, the process itself gets designed. Once the process is designed, then it must be developed. Once the process is developed it gets put into operations; it is scaled for operations and deployed to the various locations where it might need to operate. Then the process itself gets managed as service/product moves through it. The same process is then studied and improved continuously. Though not depicted here, process itself can also retire.

The Lean Practitioner knows that the process tools in the Lean toolbox can be used at different points in the process lifecycle to develop sound process understanding and enable excellent performance. I refer to this as Process Design and Development Methodology (TM) and will speak to it in future blog posts.