W. Edward Deming said, “If you can’t describe what you are doing as a process, then you don’t know what you are doing”. The fact of the matter is that process can be described at different levels of detail and organizations struggle with knowing which level is appropriate in a given situation. If we discuss process at too high a level, we fail to have the language that describes the actual work and our focus shifts from the process to the people. If we discuss process in too much detail, we might become too prescriptive and inflexible in the doing of the work. Our task, as process experts, is to develop both the sense and the know-how to navigate between the different levels of resolution that exist for a given process and to discern what level of detail is appropriate to help the business understand its work.

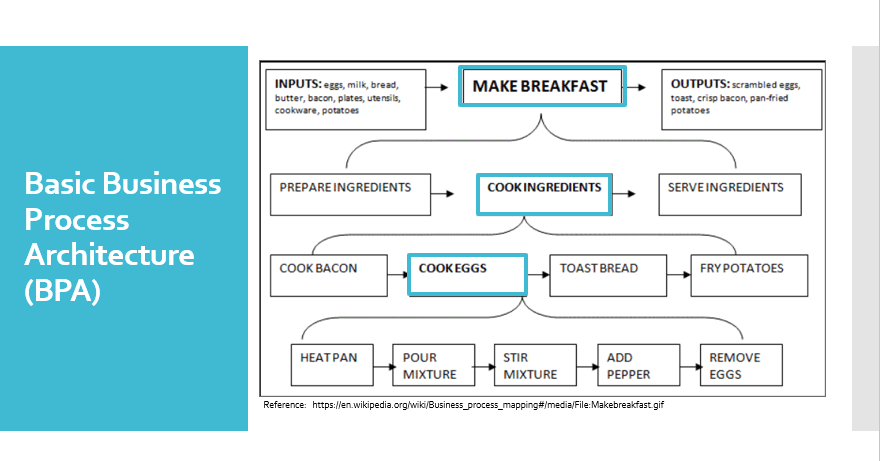

To develop this skill, we first need an awareness of the different levels of detail found in a process. Together, the “nested” levels are what is called “Business Process Architecture” (BPA). The diagram here comes from Wikipedia (emphasis added) and is a good illustration of a basic BPA. In the rest of this blog, I will point out a few important points for your consideration.

At the highest level, in this example, we want to “Make Breakfast”. We can see the inputs needed and the resulting output of the [Making Breakfast] process. However, the description of the work at the highest level is not sufficient for us to actually understand the work. This means the highest-level step might need to be described in more resolution: Prepare Ingredients, Cook Ingredients, Serve Ingredients.

Observe, each of these steps can be further described by even more detailed steps. For instance, the [Cook Ingredients] step is made up of: Cook bacon, cook eggs, toast bread, fry potatoes. Notice this diagram only expands the [Cook Ingredients] step, yet each of the steps can be explained in more detail. While not depicted here, even the most detailed steps can be further expanded. For example, [Heat Pan] can also be described in more resolution.

Language is important. Notice that all the process steps are actions. In other words, each begins with a verb. Also notice that at the highest level, inputs are identified, and outputs are described. An input can be a material or information needed to perform the process and is typically described as a noun. The outputs refer to what is the product of the process. Said another way, what is the result of performing the process steps on the inputs. Often outputs are described using nouns along with adjectives. This is especially the case when describing knowledge work and/or transactional work.

In this diagram, Inputs/Outputs are described at the highest level. Indeed, you might recognize some of the elements in a SIPOC diagram depicted here. However, if you take a moment to think of it, inputs and outputs can be identified for each process step at the more detailed description level. In fact, not all the inputs are needed for every step in the process. This is important because it is relevant to the process-mapping we do in the organizations we serve. Many times, we apply the SIPOC tool without actually linking the inputs to the point of work where it is actually needed. When we fail to make this linkage at the more granular level, we are left with gaps in our understanding. Inputs and outputs can be identified for each step in the process. In this diagram, for instance, bacon is only needed in the [cook bacon] step, similarly eggs and bread are only needed for those steps.

One last point I’d like to emphasize is, when describing process, we use the term “step” generically. Indeed, we use the term “step” to represent the work at each level of detail. This language can be confusing because the amount of work involved in each step might not be the same depending on the level within the BPA. In my next blog, I will introduce you to the KT process level structure which will give us a common framework and language to describe the process at the different levels of detail necessary to understand the work we do.

Process exists in different levels of detail within the BPA. It is important that we, as process experts, understand this and are equipped with the know-how to help the business work through the detail needed to understand and solve real business problems. Deming was right. In the absence of detailed process understanding we literally do not know what we are doing.

NOTE: For more on Process Design and Development, check out my course on Udemy. https://www.udemy.com/course/process-design-and-development/?referralCode=6D83C27A243FB023A413